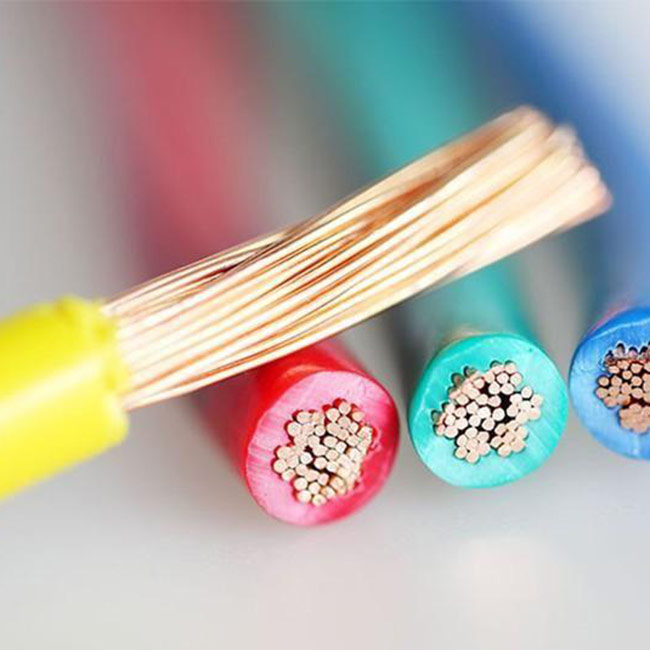

Advanced automation and electrical engineering for precise control of the cable mixing and manufacturing process

Integrated solution of customised switchboards, PLC programming and supervision to optimise quality, efficiency and safety

Challenge

Ensuring automated and precise control of raw material dosing and mixing, with optimal speed and quality management of the cable manufacturing process. It was essential to ensure operational reliability and safety, along with easy maintenance and consultation of technical documentation for quick and targeted interventions.

Results/benefits achieved by the customer

- Custom-designed and wired switchboards for reliable and modular control

- Dedicated PLC programming for synchronised control of the mixing and extrusion process

- Integration with supervisory systems for real-time monitoring, data collection and remote control

- Optimisation of the production process with precise control of quality and production speeds

- Improved operational safety and ease of maintenance through clear and accessible documentation

- Increased finished product quality and reduced production waste