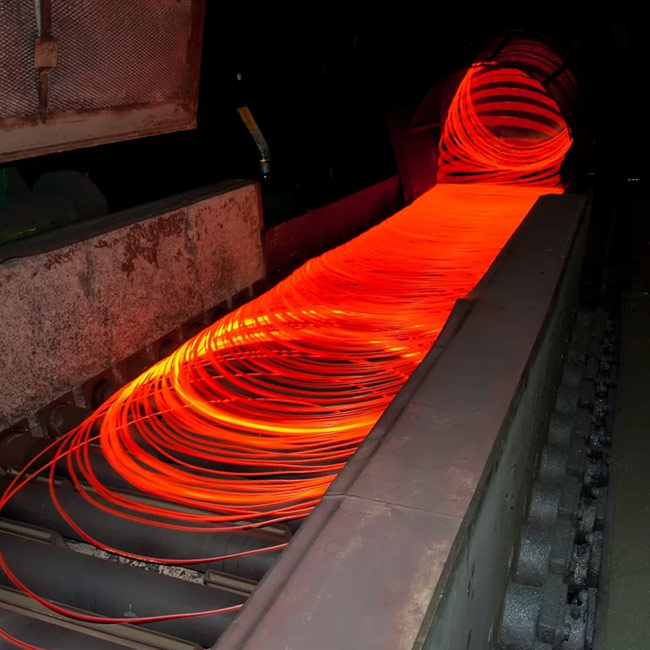

Complete automation for hot and cold rolling mill plant

Implementation of integrated automation system with advanced control and remote assistance for high-performance rolling mills

Challenge

The project addressed the complexity of simultaneously controlling multiple process variables in the hot and cold rolling phases, requiring a unified and intuitive interface for complete plant management. High standards of accuracy and reliability had to be guaranteed, minimising downtime and preparing the engineering for future upgrades and integrations in view of Industry 4.0.

Results/benefits achieved by the customer

- Single, user-friendly interface for integrated control of the rolling plant.

- Dedicated software for synergic management of rolling mill, speed, pulls and thicknesses, improving quality and productivity.

- Timely technical assistance during cold and hot trials, with remote support for timely intervention.

- Accurate and customised commissioning to optimise production performance.

- Scalable and modular architecture, ready for future developments and integration with Industry 4.0 technologies.